Contact Us

Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

Product : Coating Thickness Gauge

Model : DC30FH

Country of Origin : CHINA

Brand : DTEC

Quality Certified : CE,GB/T 17394-1998, ASTM A956

Delivery Time : 3 days

Packing Weight : 2KG

Dimension : 30x23x8cm (LxWxH)

Package Type : Maker's Standard Export Carton Box

Courier : DHL/TNT/FedEx/UPS/EMS,Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

DC30FH Coating Thickness Gauge one of the three models of DC30 series coating thickness gauge, which equips with high class ferrous probe F10,which can measure the coating up to 10000μm, adopting magnetic measuring method to measure the thickness of non-magnetic coatings on magnetic metal substrates. Such coatings including paint,plastic film,chromium layer,copper layer, zinc coating, enamel etc.

It is widely used in electronics, power plants, petrochemical industry, aviation, architecture etc.

Using Scopes:

With ferrous probe, it is used to measure non-magnetic coatings on magnetic metal substrates.

►Common non-magnetic coatings:

Painting coating(oil paint, painting, powder spraying), plastic film,rubber layer,erosion resistant coating,synthetic material layer,chromium layer,copper layer, lead layer, aluminum layer, tin layer, cadmium layer, zinc coating, enamel etc..

►Common magnetic metal substrates:

Steel, iron base alloys, cobalt, nickel etc..

Measuring principle of DC30 Series:

►Magnetic Method (Fe): Measuring the thickness of non- magnetic coatings on steel, iron and other ferromagnetic metal substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, phosphate coating, chromium, zinc, Aluminum, tin and cadmium, etc.

►Eddy Current Method (NFe): measuring the thickness of non-conductive coatings on copper, aluminum, stainless steel and other non-ferromagnetic substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, oxide film and phosphate film, etc.

It is widely used in electronics, power plants, petrochemical industry, aviation, architecture etc.

Using Scopes:

With ferrous probe, it is used to measure non-magnetic coatings on magnetic metal substrates.

►Common non-magnetic coatings:

Painting coating(oil paint, painting, powder spraying), plastic film,rubber layer,erosion resistant coating,synthetic material layer,chromium layer,copper layer, lead layer, aluminum layer, tin layer, cadmium layer, zinc coating, enamel etc..

►Common magnetic metal substrates:

Steel, iron base alloys, cobalt, nickel etc..

Measuring principle of DC30 Series:

►Magnetic Method (Fe): Measuring the thickness of non- magnetic coatings on steel, iron and other ferromagnetic metal substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, phosphate coating, chromium, zinc, Aluminum, tin and cadmium, etc.

►Eddy Current Method (NFe): measuring the thickness of non-conductive coatings on copper, aluminum, stainless steel and other non-ferromagnetic substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, oxide film and phosphate film, etc.

►Large measuring range of ferrous probe:0-10000μm;

►Standard data processing software and USB cable, enable to connect to PC for further data analysis and data print;

►Multiple statistics function: Measuring Times, Max, Min, Average, and Standard Deviation;

►High Contrast Segment Liquid Crystal Display (LED Backlight);

►Suitable for both One-Point Calibration and Two-Point Calibration;

►Auto off after 3 minutes of inactivity to save power;

►Excellent after-sale service system for high quality products. Easy to buy and convenient to use.

►Standard data processing software and USB cable, enable to connect to PC for further data analysis and data print;

►Multiple statistics function: Measuring Times, Max, Min, Average, and Standard Deviation;

►High Contrast Segment Liquid Crystal Display (LED Backlight);

►Suitable for both One-Point Calibration and Two-Point Calibration;

►Auto off after 3 minutes of inactivity to save power;

►Excellent after-sale service system for high quality products. Easy to buy and convenient to use.

|

Model

|

DC30FH

|

|

|

Measuring Principle

|

Magnetic Method

|

|

|

Measuring Range (μm)

|

F10 Probe:0-10000

|

|

|

Indication Resolution

|

1

|

|

|

Indication Error (μm)

|

±(2%H+10)

|

|

|

Repeatability (μm)

|

±(1%H+10μm)

|

|

|

Measuring Condition (mm) |

Min. Curvature Radius(convex)

|

10

|

|

Min. Measuring Surface

|

Φ 40

|

|

|

Min. Substrate Thickness |

2

|

|

|

Display

|

High Contrast Segment Liquid Crystal Display (display only figure) (LED Backlight) |

|

|

Statistics Function

|

Measuring Times, Max, Min, Average, and Standard Deviation |

|

|

Calibration Mode

|

One point and Two Point

|

|

|

Working Temperature

|

-10℃~+50℃, -20℃ in special requirement

|

|

|

Auto Power off

|

Auto off after 3 minutes of inactivity |

|

|

Power Supply

|

Two AA size batteries, low-voltage indication function |

|

|

Dimension

|

30x23x8cm (LxWxH)

|

|

|

Packing Weight

|

2 KG

|

|

Standard Packing List:

Optional Accessories:

►F1 Probe:

►N1 Probe:

►F10 Probe:

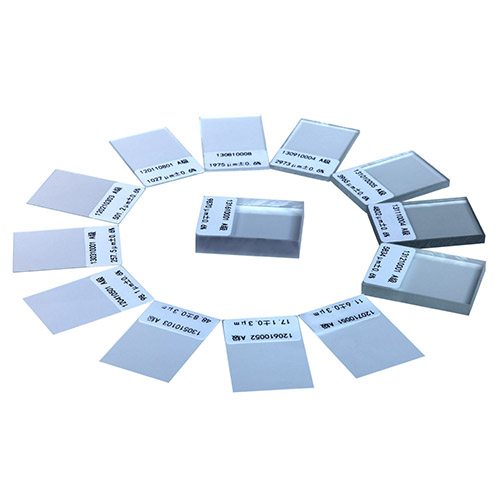

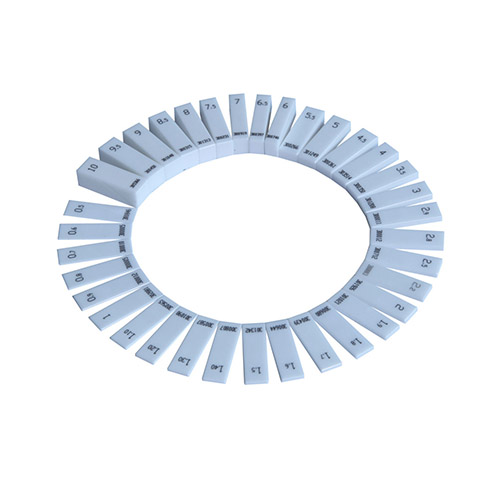

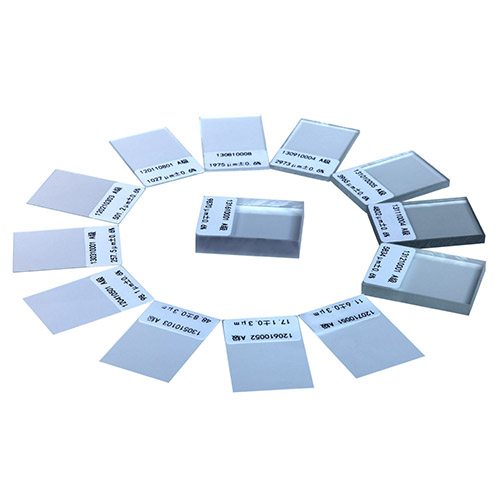

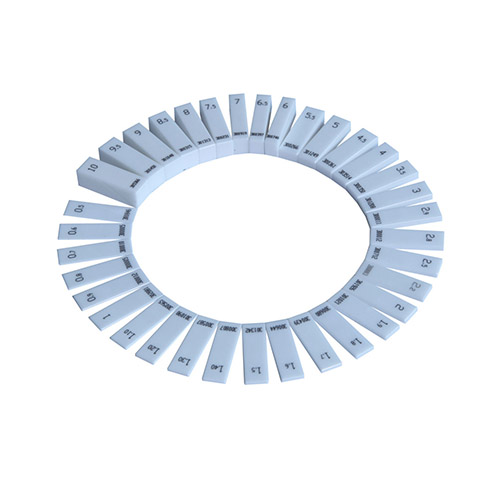

►Plastic Calibration Foils:

►Ceramic Calibration Foils:

►Fe Zero Plate:

►Al Zero Plate:

►DC30 Series Instrument Case:

|

No.

|

Items

|

Qty.

|

|

1

|

DC30FH Coating Thickness Gauge Main Unit |

1

|

|

2

|

F10 Ferrous Probe

|

1

|

|

3

|

Calibration Foils

|

5

|

|

4

|

Zero Plate (Fe)

|

1

|

|

5

|

Data Processing Software and USB Cable |

1 each

|

|

6

|

Instrument Case

|

1

|

|

7

|

Manual, Guarantee Card, Quality Certificate |

1 each

|

Optional Accessories:

|

No.

|

Items

|

|

1

|

Plastic Calibration Foils |

|

2

|

Ceramic Calibration Foils |

|

3

|

Fe Zero Plate

|

|

4

|

Al Zero Plate

|

|

5

|

F1 Ferrous Probe

|

|

6

|

N1 Non-ferrous Probe

|

|

7

|

F10 Ferrous Probe

|

| 8 | Instrument Case |

►F1 Probe:

►N1 Probe:

►F10 Probe:

►Plastic Calibration Foils:

►Ceramic Calibration Foils:

►Fe Zero Plate:

►Al Zero Plate:

►DC30 Series Instrument Case: