Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

Product : Coating Thickness Gauge

Model : DC30N

Country of Origin : CHINA

Brand : DTEC

Quality Certified : CE,GB/T 17394-1998, ASTM A956

Delivery Time : 3 days

Packing Weight : 2KG

Dimension : 30x23x8cm (LxWxH)

Package Type : Maker's Standard Export Carton

Courier : DHL/TNT/FedEx/UPS/EMS,Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

It is widely used in electronics, power plants, petrochemical industry, aviation, architecture etc.

Using Scopes:

With non-ferrous probe, it is used to measure non-conductive coatings on non-magnetic substrates.

►Common non-conductive coatings:

Painting coating(oil paint, painting, powder spraying), plastic film,rubber layer,erosion resistant coating,synthetic material layer,chromium layer,copper layer, lead layer, aluminum layer, tin layer, cadmium layer, zinc coating, enamel etc..

►Common non-magnetic metal substrates:

Copper,Stainless Steel Aluminum,Gold,Silver and almost all the metals except iron, cobalt and nickel.

Measuring principle of DC30 Series:

►Magnetic Method (Fe): Measuring the thickness of non- magnetic coatings on steel, iron and other ferromagnetic metal substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, phosphate coating, chromium, zinc, Aluminum, tin and cadmium, etc.

►Eddy Current Method (NFe): measuring the thickness of non-conductive coatings on copper, aluminum, stainless steel and other non-ferromagnetic substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, oxide film and phosphate film, etc.

►Standard data processing software and USB cable, enable to connect to PC for further data analysis and data print;

►Wide measuring range of non-ferrous probe:0-2000μm;

►Multiple statistics function: Measuring Times, Max, Min, Average, and Standard Deviation;

►High Contrast Segment Liquid Crystal Display (LED Backlight);

►Suitable for both One-Point Calibration and Two-Point Calibration;

►Auto off after 3 minutes of inactivity to save power;

►Excellent after-sale service system for high quality products. Easy to buy and convenient to use.

|

Model

|

DC30N

|

|

|

Measuring Principle

|

Eddy Current Method

|

|

|

Measuring Range (μm)

|

N1 Probe:0-2000

|

|

|

Indication Resolution

|

0.1

|

|

|

Indication Error (μm)

|

±(2%H+2)

|

|

|

Repeatability (μm)

|

±(1%H+1μm)

|

|

|

Measuring Condition (mm) |

Min. Curvature Radius(convex)

|

3

|

|

Min. Measuring Surface

|

Φ 5

|

|

|

Min. Substrate Thickness |

0.3

|

|

|

Display

|

High Contrast Segment Liquid Crystal Display (display only figure) (LED Backlight) |

|

|

Statistics Function

|

Measuring Times, Max, Min, Average, and Standard Deviation |

|

|

Calibration Mode

|

One point and Two Point

|

|

|

Working Temperature

|

-10℃~+50℃, -20℃ in special requirement

|

|

|

Auto Power off

|

Auto off after 3 minutes of inactivity |

|

|

Power Supply

|

Two AA size batteries, low-voltage indication function |

|

|

Dimension

|

30x23x8cm (LxWxH)

|

|

|

Packing Weight

|

2 KG

|

|

|

No.

|

Items

|

Qty.

|

|

1

|

DC30N Coating Thickness Gauge Main Unit |

1

|

|

2

|

N1 Non-ferrous Probe

|

1

|

|

3

|

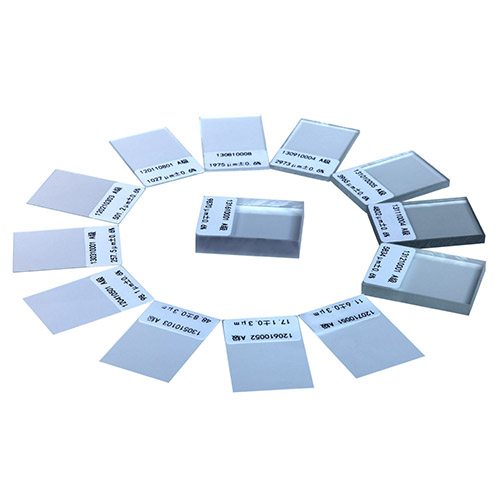

Calibration Foils

|

3

|

|

4

|

Zero Plate (Al)

|

1

|

|

5

|

Data Processing Software and USB Cable |

1 each

|

|

6

|

Instrument Case

|

1

|

|

7

|

Manual, Guarantee Card, Quality Certificate |

1 each

|

Optional Accessories:

|

No.

|

Items

|

|

1

|

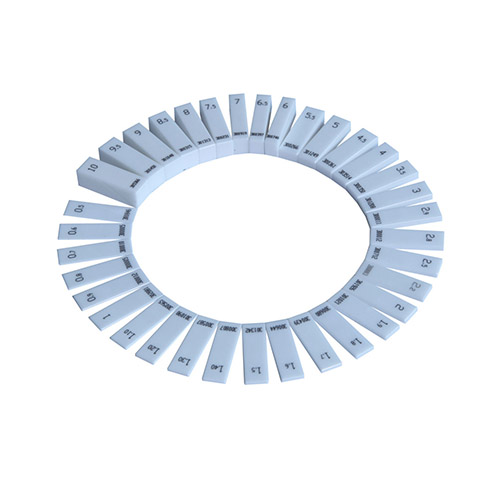

Plastic Calibration Foils |

|

2

|

Ceramic Calibration Foils |

|

3

|

Fe Zero Plate

|

|

4

|

Al Zero Plate

|

|

5

|

F1 Ferrous Probe

|

|

6

|

N1 Non-ferrous Probe

|

|

7

|

F10 Ferrous Probe

|

►F1 Probe:

►N1 Probe:

►F10 Probe:

►Plastic Calibration Foils:

►Ceramic Calibration Foils:

►Fe Zero Plate:

►Al Zero Plate:

►DC30 Series Instrument Case: