Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

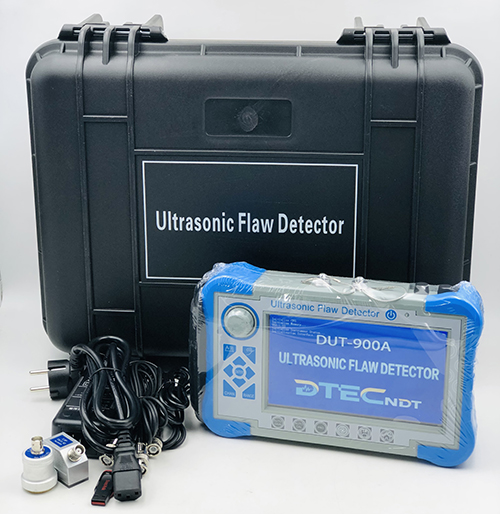

Product : Touch Screen Ultrasonic Flaw Detector

Model : DUT-900A

Country of Origin : CHINA

Brand : DTEC

Quality Certified : CE,ISO

Delivery Time : 3 days

Packing Weight : 6KG

Dimension : 45x38x23cm(LxWxH)

Package Type : Maker's Standard Export Carton Box

Courier : DHL/TNT/FedEx/UPS/EMS/Shipping Agent

Payment Term : TT100%/Private Bank Account/Credit Card/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

- High-precision quantification and positioning to meet the requirements of near and far distance detection.

- The near-field blind zone is small, can meet the detecting requirements for small-diameter and thin-walled pipe.

- Auto calibration function:one-button auto calibration,easy to operate, automatic test probe “P Delay”,”K value”,”X value” and the velocity

- Automatic display the defect echo position(Depth:d, Horizontal:p,Distance:s, Amplitude,dB )

- Switch three scales freely(Depth:d, Horizontal:p,Distance:s)

- Auto gain, peak envelope, peak memory functions, which can improve the detection efficiency.

- Automatically record the flaw detection process and dynamic playback

- value calculation:Forging flaw detection by straight probe, can find the highest wave to conversion φ value automatically

- 500 independent channels(can be expandable), which can input and store the detection standards of any industries freely, do not need to carry the standard blocks for on-site inspection.

- Store, playback 500 A-scan waves and data freely

- The DAC, AVG, and TCG curves (depth compensation) are automatically generated and can be segmented. The sampling points are unrestricted and can be corrected and compensated.

- 14 built-in inspection standards

- Free to enter any industry standards

- Pulse width and strength can adjustable

- B scan and B color scan function;

- Can communicate with the computer, and export WORD. File, also the detection report;

- IP65 ABS plastic case, sturdy and durable,water-proof and dust-proof, and excellent anti-interference ability;

- Use (wireless) communication software to analyze data print reports, etc;

- 260,000-color true color screen, is suitable for working environment under strong light or low light;

- High performance lithium battery, can work continuously for 8-10 hours;

- Real-time clock recording: real-time flaw detection date, time tracking record, and storage;

- Power-down protection, storage data can not lost;

- Flaw detection parameters can be automatically tested or preset;

- Digital reject, does not affect gain and linearity;

- Gain compensation: Db attenuation can be corrected for surface roughness, curved surfaces, long-range flaw detection of thick work-pieces, etc.;

- Can operate the flaw detector by software at the PC, achieving the goal of computer-controlled flaw detector to detecting.

|

Display

|

7 inch TFT color screen,800*480 resolution

|

|

Operation mode

|

Button, Rotary, Touch Screen

|

|

Power supply

|

Lithium Ion Battery

|

|

Battery capacity

|

5.0Ah

|

|

Power voltage

|

12V

|

|

Power quantity

|

1

|

|

Working time

|

≥8 hours

|

|

Adapter input

|

DC100~240V 50Hz/60Hz

|

|

Adapter output

|

AC 12V

|

|

Adapter power

|

36W

|

|

Data storage

|

SD card(16G)

|

|

Alarm

|

1

|

|

Working Temperature

|

-10℃~45℃

|

|

Storage Temperature

|

-20℃~60℃

|

|

IP Grade

|

IP65

|

|

Dimension

|

245*155*55mm

|

|

Weight

|

1.18kg(included battery)

|

|

Conventional UT Model

|

|

|

Probe Connector type

|

C5

|

|

Channel Type

|

Single channel

|

|

Channel Num

|

500 group(able to be scaled)

|

|

Pulse Type

|

Negative sharp wave

|

|

Transmit Voltage

|

50~350V,step in 50V

|

|

Damping

|

560Ω

|

|

Gain

|

0~110dB,step:0.5/2/6/12dB

|

|

Gain Fine Adjustment

|

-4~+4

|

|

Surface compensation

|

All Gain Range

|

|

Working Frequency

|

0.5~20MHz;

|

|

Probe Type

|

Single,Dual, Through, Immersion type

|

|

Filter

|

Three optional:

1~4MHz/0.5~10MHz/2~20MHz

|

|

Detection Mode

|

Negative/Positive/Two-way/RF

|

|

Reject

|

0~80%,step 1%

|

|

Testing Range

|

0~15000mm,Minimum display range:15mm(in steel)

|

|

Material Velocity

|

100~20000m/s

|

|

Pulse displacement

|

-10~1000mm

|

|

P DELAY

|

0~200us

|

|

X-VAL

|

0~100mm

|

|

Guide

|

Weld, Sheet, Forging inspection

|

|

Testing Point

|

Peak/X-val/J val

|

|

Measurement

|

Gate:Amplitude,Amplitude dB value,Range,Horizontal distance,Vertical distance,The difference value between A and B Gate

Cursor:2 cross cursors, can test the horizontal and vertical distance, and the distance between cursors(under B scan function)

|

|

Gate

|

Gate start:all range

|

|

Gate width:all range

|

|

|

Gate level:10~90%,step:1%

|

|

|

Curve

|

DAC, maximum six curves, meet to NB/T 47013,GB/T 11345,GB/T 29712, and other standards

|

|

TCG, maximum six curves

|

|

|

AVG

|

|

|

Other functions

|

Full screen, cursor switch(range/Height/Horizon), single/continuous auto gain(10~100%, step 10%), echo compare,echo full, peak envelope,peak memory,fast scan,outside mode,screenshot

|

|

Peak freeze/Crack depth/Gate expansion//curved surface modification/ B scan/Flat weld simulation//video

|

|

|

Alarm

|

Sound and light alarm

|

|

Sensitivity Leavings

|

≥65dB(200mm—Φ2FH,2.5PΦ20)

|

|

Horizontal linearity error

|

≤0.3%

|

|

Vertical linearity error

|

≤3%

|

|

Amplitude linearity error

|

≤±2%

|

|

Attenuator accuracy

|

20dB ±1 dB

|

|

Dynamic range

|

≥32dB

|

|

Distant resolution

|

≥26dB

|

|

Noise Level

|

<40×10-9 V/

|

Standard Packing List:

|

|

Items |

Qty. |

|

1 |

Main unit with back supporter(LEMO or BNC port) |

1 Pcs. |

|

2 |

1.5A/9V power adaptor |

1 Pcs. |

|

3 |

probe connecting cables |

2 Pcs. |

|

4 |

Data Pro Software disk and USB cable |

1 Set |

|

5 |

Straight probe 10mm 2.5MHz |

1 Pcs. |

|

6 |

Angle probe 13x13 60°2.5MHz |

1 Pcs. |

|

7 |

Manual, QC certificate, warranty card |

1 Pcs. each |

|

8 |

Instrument Case |

1 Pcs. |

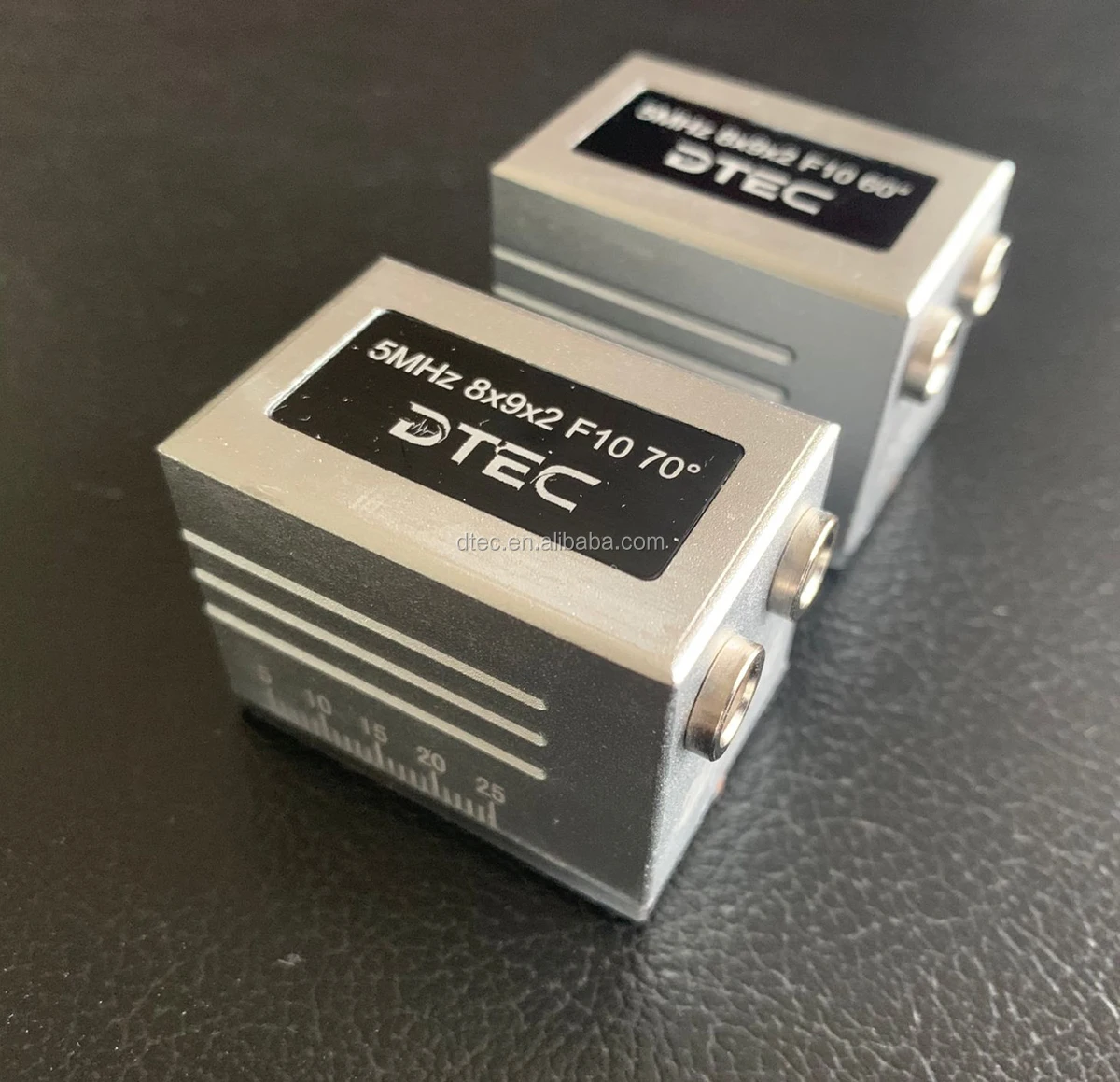

UT Probes:

All probe specification can be customized according to your requirement.

Plese do inform me the folowing information when you need UT probes:

1):Probe type(Angle Probe or Straight Probe);

2):Angle(40C,60C,70C or others);

3):Crystal Size(normal size:8x9mm);

4)Frequency(normal 2MHz,4MHz).

The probe price mainly depends on the crystal size.

And the frequecy can be chosed by yourself in the range of 0.2MHz~10MHz. For other parameters like angle,we can provide the general angles such as 30°,45°,60°,70°,80°.

General Specification of UT Probe:

| Crystal Size | 5-25mm |

| Crystal Type | Single or Double Crystal |

| Crystal Angle | 0°-70° |

| Testing Range |

1mm-280mm(according to required focus distance) |

| Center Frequency | 2-8MHz |

| Test Standard Based | EN12668-2 |

| Material | Stainless Steel |

| Sensitivity | 52-54dB |

| Resolution | 34dB |

| Initial Pulse Width | 3mm |

| Angular deviation | ±1° |

| Electrical Impedance | 49Ω |

| Working Temperature | -5-50°C |