Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

Product : DC220 Series Coating Thickness Gauge

Model : DC220 Series

Country of Origin : CHINA

Brand : DTEC

Quality Certified : ISO,National Standard

Delivery Time : 3 days

Packing Weight : 2KG

Dimension : 25x20x10cm

Package Type : Maker's Standard Export Carton Box

Courier : DHL/TNT/FedEx/UPS/EMS,Shipping Agent

Payment Term : TT100%/Private Bank Account/Credit Card/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

Magnetic Method (Fe): Measuring the thickness of non- magnetic coatings on steel, iron and other ferromagnetic metal substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, phosphate coating, chromium, zinc, Aluminum, tin and cadmium, etc.

Eddy Current Method (NFe): measuring the thickness of non-conductive coatings on copper, aluminum, stainless steel and other non-ferromagnetic substrates, e.g. painting, varieties of anti-corrosion coating, powder spraying, plastic, rubber, synthetic material, oxide film and phosphate film, etc.

APPLICATION SCOPE

1.With ferrous probe, it is used to measure non-magnetic coatings on magnetic metal substrates.

Painting coating(oil paint, painting, powder spraying), plastic film,rubber layer,erosion resistant coating,synthetic material layer,chromium layer,copper layer, lead layer, aluminum layer, tin layer, cadmium layer, zinc coating, enamel etc..

2.With non-ferrous probe, it is used to measure non-conductive coatings on non-magnetic substrates.

Painting coating(oil paint, painting, powder spraying), plastic film,rubber layer,erosion resistant coating,synthetic material layer,chromium layer,copper layer,

lead layer, aluminum layer, tin layer, cadmium layer, zinc coating, enamel etc.

Common non-magnetic metal substrates:

Copper,Stainless Steel Aluminum,Gold,Silver and almost all the metals except iron, cobalt and nickel.

8 types of probes are available for various application:F1,F1/90,F3,F10,F400,N1,N3,N400;

Strong metal shell,durable and stable in usage;

Standard data pro software comes;

Two measuring modes:continue/single;

Two working modes: direct mode(DITECT) and Batch mode(APPL);

5 statistic ways:Mean values/Max.values/Min.values/Testing numbers(No.)/Standard deviations(S.Dev);

Two measuring calibration modes;

With backlight display;

640 measured values can be stored;

Low battery indication;

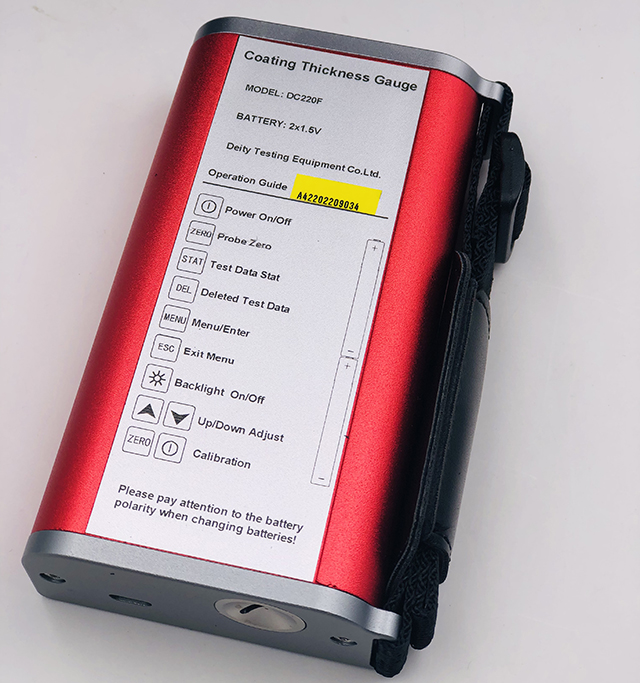

2 switch off modes: manual and auto.

|

Probe available

|

F400

|

F1

|

F1/90°

|

F10

|

F3

|

N400

|

N1

|

N3

|

|||||||||

|

Measuring range(um) |

0-400

|

0-1250

|

0-10000

|

0-3000

|

0-400

|

0-1250

|

0-3000

|

||||||||||

|

Accuracy

|

|

|

|

|

|

|

|

|

|||||||||

|

Accuracy

|

One-point calibration (µm) |

±(3%H+1)

|

±(3%H+10)

|

±(3%H+5)

|

±(3%H+0.7)

|

±(3%H+10)

|

±(3%H+5)

|

||||||||||

|

Two-point calibration (µm) |

±[(1-3)H%+0.7]

|

±[(1-3)H%+1]

|

±(3%H+10)

|

±[(1-3)%H+1.5]

|

±[(1-3%H+0.7)

|

±(3%H+1.5)

|

±(3%H+5)

|

||||||||||

|

Minimum resolution(um)

|

0.1

|

0.1

|

10

|

1

|

0.1

|

0.1

|

0.5

|

||||||||||

|

Measuring conditions |

Min curvature of the min area (mm) |

Convex

|

1

|

5

|

flat

|

10

|

3

|

Convex

|

1.5

|

3

|

3

|

||||||

|

Diameter of the min area (mm) |

φ3

|

φ7

|

φ20

|

φ40

|

φ5

|

F4

|

F5

|

F5

|

|||||||||

|

Critical thickness of substrate (mm) |

0.2

|

0.5

|

1

|

2

|

0.3

|

0.3

|

0.3

|

0.3

|

|||||||||

|

Operation language |

English/Russian/Spanish

|

φ3

|

φ7

|

F20

|

φ40

|

φ5

|

|||||||||||

|

Standards

|

DIN,ISO,ASTM,BS

|

0.2

|

0.5

|

1

|

2

|

0.3

|

|||||||||||

|

Calibration

|

Zero and foil calibration |

||||||||||||||||

|

Interface

|

USB

|

||||||||||||||||

|

Statistic

|

Number of measurement, mean, standard deviation, maximum and minimum |

||||||||||||||||

|

Data memory

|

640 readings

|

||||||||||||||||

|

Limits

|

Adjustable with alarm |

||||||||||||||||

|

Power supply

|

NiMH rechargeable battery |

||||||||||||||||

|

Dimensions(mm)

|

230×86×47

|

||||||||||||||||

|

Operating environment |

Temperature:0~40C

|

||||||||||||||||

|

Humidity:20%~90%

|

|||||||||||||||||

|

No strong magnetic field |

|||||||||||||||||

Optional Probes and Application Guide

|

Probe model |

F400

|

F1

|

F1/90º |

F10

|

F3

|

||

|

Operating principle |

Magnetic induction |

||||||

|

Measuring range (µm) |

0-400

|

0-1250

|

0-10000

|

0~3000

|

|||

|

Low range resolution (µm) |

0.1

|

0.1

|

10

|

1

|

|||

|

Accuracy

|

One-point calibration (µm) |

±(3%H+1)

|

±(3%H+10)

|

±(3%H+5)

|

|||

|

Two-point calibration (µm) |

±[(1~3)H%+0.7]

|

±[(1~3)H%+1]

|

±((1~3)%H+5)

|

±[(1~3)%H+1.5]

|

|||

|

Measuring conditions |

Min curvature of the min area (mm) |

Convex

|

1

|

5

|

Flatten

|

10

|

3

|

|

Diameter of the min area (mm) |

φ3

|

φ7

|

F20

|

φ40

|

φ5

|

||

|

Critical thickness of substrate (mm) |

0.2

|

0.5

|

1

|

2

|

0.3

|

||

|

Probe model |

N400 |

N1

|

N3

|

||

|

Operating principle |

Eddy current

|

||||

|

Measuring range (µm) |

0~400 |

0~1250

|

0~3000

|

||

|

Low range resolution (µm) |

0.1

|

0.1

|

0.5

|

||

| Accuracy |

One-point calibration (µm) |

±(3%H+0.7)

|

±(3%H+1.5)

|

±(3%H+5)

|

|

|

Two-point calibration (µm) |

±[(1~3%H+0.7)

|

±[(1~3)%H+1.5]

|

±((1~3)%H+5)

|

||

|

Measuring conditions |

Min curvature of the min area (mm)

|

Convex

|

1.5

|

3

|

3

|

|

Diameter of the min area (mm) |

F4

|

F5

|

F5

|

||

|

Critical thickness of substrate (mm) |

0.3

|

0.3

|

0.3

|

||

Reference Table for Probe selection

|

Substrate Coatings

|

Non-magnetism coatings (Organic materials) |

Non-magnetism coatings(nonferrous metals) |

|||

|

Thickness of coatings is more than 100 |

|||||

|

Steel,iron and other magnetism metal |

Diameter of tesitng area is more than 30mm |

F1 probe:0~1250 µm F400 probe:0~400µm |

F1 probe:0~1250 µm F10 probe:0~10µm

|

F400probe:0~400 µm F1probe:0~1250µm

|

F1 probe:0~1250

F10µm probe:0~10µm |

|

Diameter of testing are is less than 30mm |

F400 probe:0~400µm |

F1 probe:0~1250 µm F400 probe:0~400µm |

F400probe:0~400µm

|

F400 probe:0~400

F1µm probe:0~1250µm |

|

|

Copper,Brass,Aluminum,Zinc,Tin and other metallic |

Diameter of testing area is more than 5mm |

N1 probe:0~1250µm

|

N1 probe:0~40µm

(For chromeplate on copper) |

||

|

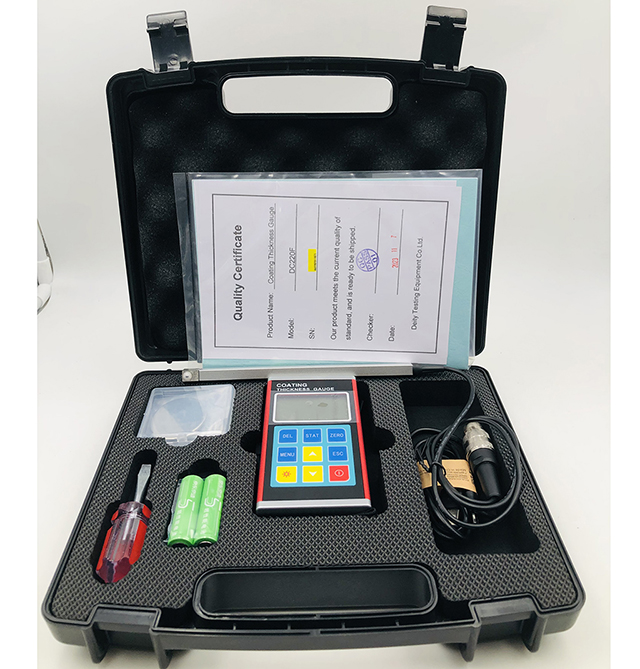

ITEMS

|

QTY.

|

|

Main unit |

1

|

|

Probe(F1/N1)

|

1

|

|

Substrate

|

5

|

|

Calibration foil |

1

|

|

Instruction manual |

1

|

|

Communication cable |

1

|

|

Dataview software |

1

|