Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

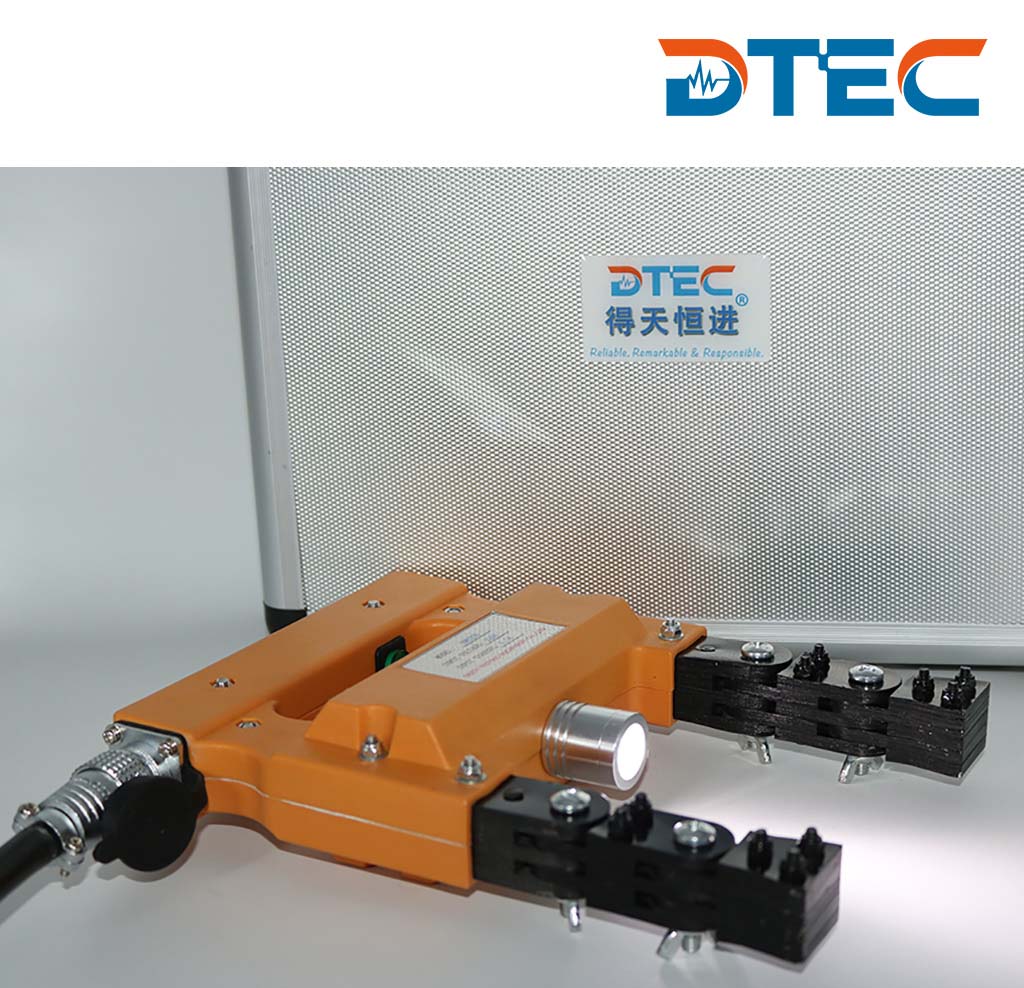

Product : DMY220 Magnetic Yoke Flaw Detector

Model : DMY220

Country of Origin : CHINA

Brand : DTEC

Quality Certified : ISO,CE

Delivery Time : 3 days

Packing Weight : 8-11KG

Dimension : 42x42x38cm(LxWxH)

Package Type : Maker's Standard Export Wooden Case

Courier : DHL/TNT/FedEx/UPS/EMS/Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

DMY series Magnetic Yoke Flaw Detector is a kind of portable magnetic flaw detector, which employs the yoke to produce magnetization on the ferromagnetic material. There are three types of magnetic yoke flaw detector according to different power source, AC, DC and AC-DC dual use. DC power source is rechargeable battery, it is applicable to field operation with no power supply and high voltage which can not enter the field, such as container, bridges, pipelines and other field operations; with 6 continuous working hours after a full charge. AC power source adopts 220V directly supplied power, without the need of ancillary equipment, with easy operation, simple, light weight, easy to carry, hence, this equipment is widely used.

Application:

Magnetic Yoke Flaw Detector can make magnetization to various components of, They are applicable to oil, shipbuilding, engine parts, coal, machinery, standard parts, oil pump and nozzle, aircraft manufacturing, automobile other pieces, bridge-building, chemical industry, boiler and pressure vessel, railways and other industry products, due to forging, quenching, welding, fatigue caused by surface and near surface defects, such as chain rod, crankshaft, bearings, high strength bolts, springs, forgings, petrochemical pipe fittings, valves, blades, gears, rollers, chains and complex geometry such as weld inspection of the workpiece.

DC crack detection (DMY12-220 DMY12):

1) Connect the Yoke to the storage battery, hence it supply power to the yoke;

2) Before detecting, put the yoke probe on the surface of workpiece and make sure the well contact;

3) Switch on and then spray the powder or magnetic suspension to the testing area, and maintain 2 ~ 3s;

4) Release the switch and remove the yoke, check the specimen;

5) Change a new area and test again, repeat Steps 3) and 4).

AC crack detection (DMY12-220 DMY220):

1) Connect the power cable to the 220V power socket(make sure the socket come with ground wire and well connected);

2) While testing, do the same as above steps 3) and 4).

|

Model

|

DMY12-220

|

DMY12

|

DMY220

|

|

|

Power supply mode

|

AC-DC

|

DC

|

AC

|

|

|

Power Supply

|

220V50Hz–12V

|

–12V

|

220V50Hz

|

|

|

Charging Power

|

220V 50Hz

|

220V 50Hz

|

|

|

|

Battery

|

MF12—7.2H

|

MF12—7.2H

|

|

|

|

Working Current

|

AC1.4A/DC1.7A

|

DC1.7A

|

AC1.4A

|

|

|

Charging Time

|

8-15h

|

8-15h

|

|

|

|

Working Hours

|

Over 6 Hours

|

Over 6 Hours

|

|

|

|

Working time gap

|

One second

|

|||

|

Magnetization Pole Distance

|

50-200mm

|

50-200mm

|

50-200mm

|

|

|

Elevating Force

|

A C

|

>5.5kg

|

|

>5.5kg

|

|

D C

|

>25kg

|

>25kg

|

|

|

|

Weight

|

Yoke

|

3.2kg

|

3.2kg

|

3.2 kg

|

|

Battery Box

|

2.9kg

|

2.9kg

|

|

|

|

Dimension(㎜)

|

Yoke

|

208×52×146

|

208×52×146

|

208×52×146

|

|

Battery Box

|

160×100×70

|

160×100×70

|

|

|

|

Charger

|

80×60×40

|

80×60×40

|

|

|

|

Model

|

DMY12-220

|

DMY12

|

DMY220

|

|

Power supply mode

|

AC-DC

|

DC

|

AC

|

|

Yoke (Probe)

|

1Pcs.

|

1Pcs.

|

1Pcs.

|

|

Battery Box

|

1Pcs.

|

1Pcs.

|

|

|

Battery

|

1Pcs.

|

1Pcs.

|

|

|

Charger

|

1Pcs.

|

1Pcs.

|

|

|

Power Cable

|

1Pcs.

|

|

1Pcs.

|

|

Surrounding Cable

|

1Pcs.

|

1Pcs.

|

|

|

User’s Manual

|

1Pcs.

|

1Pcs.

|

1Pcs.

|

|

Quality Certificate

|

1Pcs.

|

1Pcs.

|

1Pcs.

|