Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

Product : Digital Micro Vickers Hardness Tester

Model : HV-1000

Country of Origin : CHINA

Brand : DTEC

Quality Certified : GB/T4340.2, ISO6507-2, ASTM E384

Delivery Time : 3 days

Packing Weight : 65KG

Dimension :

Package Type : Maker's Standard Export Wooden Case

Courier : DHL/TNT/FedEx/UPS/EMS/Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

It is a new and high-tech product combining optical, mechanical and electronic techniques. With novel appearance, good reliability, operational functions and direct viewing, it is a new type Micro Vickers and Knoop hardness measuring equipment, which adopts high-precision optical measuring systems and precision coordinate test sets.

Additionally, this equipment is suitable for optional data processing software and optional CCD measuring system. Through handing menu keys, the equipment perform complete functions such as selecting Vickers or knop hardness testing mode, adjusting the intensity of black light, setting dwell time; besides, the length of indentation diagonal line can be keyed on operating board, then directly readout the hardness value from the screen, which is free from checking the tables.

Using Application:

Carburized layer, ceramic, steel, non-ferrous metals; sheet, metal foil, plating, fine specimen;

Applicable to the test on nitride layer, the gradient measurement of carburized layer and hardened layer; Suitable for precision Vickers measurement on parallel surface and tiny precision parts and thin parts.

►Large LCD digital displaying screen, menu-driven operation structure;

►Equips with RS-232 data port, suitable to connect to PC;

►Suitable for match optional data processing software and CCD image measuring system;

►Suitable for match knoop indenter to do knop hardness test;

►Selectable and exchangeable among different hardness scales;

►Automatic testing course, easy and convenient operation without man-made error, which guarantees high testing precision;

►Machine accuracy is in line with GB/T4340.2, ISO6507-2 and American standard ASTM E384.

|

Model |

HV-1000 |

|

Testing Force |

10gf (0.098N)、25gf (0.245N)、50gf (0.49N)、100gf (0.98N)、 200gf (1.96N)、300gf (2.94N)、500gf(4.9N)、1000gf (9.8N) |

|

Carried Standard |

GB/T4340.2, ISO6507-2, ASTM E384 |

|

Exchange Scales |

HRA、HRB、HRC、HRD、HRF、HV、HK、HBW、HR15N、HR30N、HR45N、HR15T、HR30T、HR45T |

|

Testing Range |

5~3000HV |

|

Force Control Mode |

(Automatic) Loading, Dwell, Unloading |

|

Magnification of Microscope |

400X(For Measurement), 100X(For Observation) |

|

Dwell Time |

0~60s |

|

X-Y Testing Platform |

Side:100*100mm Max. Moving Distance:25*25mm |

|

Data Output |

LCD Digital Display, RS-232 port(when use software and CCD camera) |

|

Specimens Max. Height |

90mm |

|

Specimens Max. Depth |

120mm |

|

Power Supply |

AC220V, 50/60Hz |

|

Dimension |

63*40*78cm |

|

Packing Weight |

65Kg |

Standard Packing Accessories:

|

Items |

Qty. |

Items |

Qty. |

|

Weights Roller |

1 |

Diamond pyramid indenter |

1 |

|

Crossing Shape Testing Platform |

1 |

sheet Testing Platform |

1 |

|

Fine flat forcipate Testing Platform |

1 |

Filament Testing Platform |

1 |

|

Screwdriver |

2 |

Bolt Adjustor |

4 |

|

Horizontal Scroll Bar |

1 |

10X Testing Eyepiece |

1 |

|

Standard micro Vickers Block(high、low) |

1 each |

Fuse(2A) |

2 |

|

Power Cable |

1 |

Quality Certificate |

1 |

|

User’s Manual Book |

1 |

Weight |

6 |

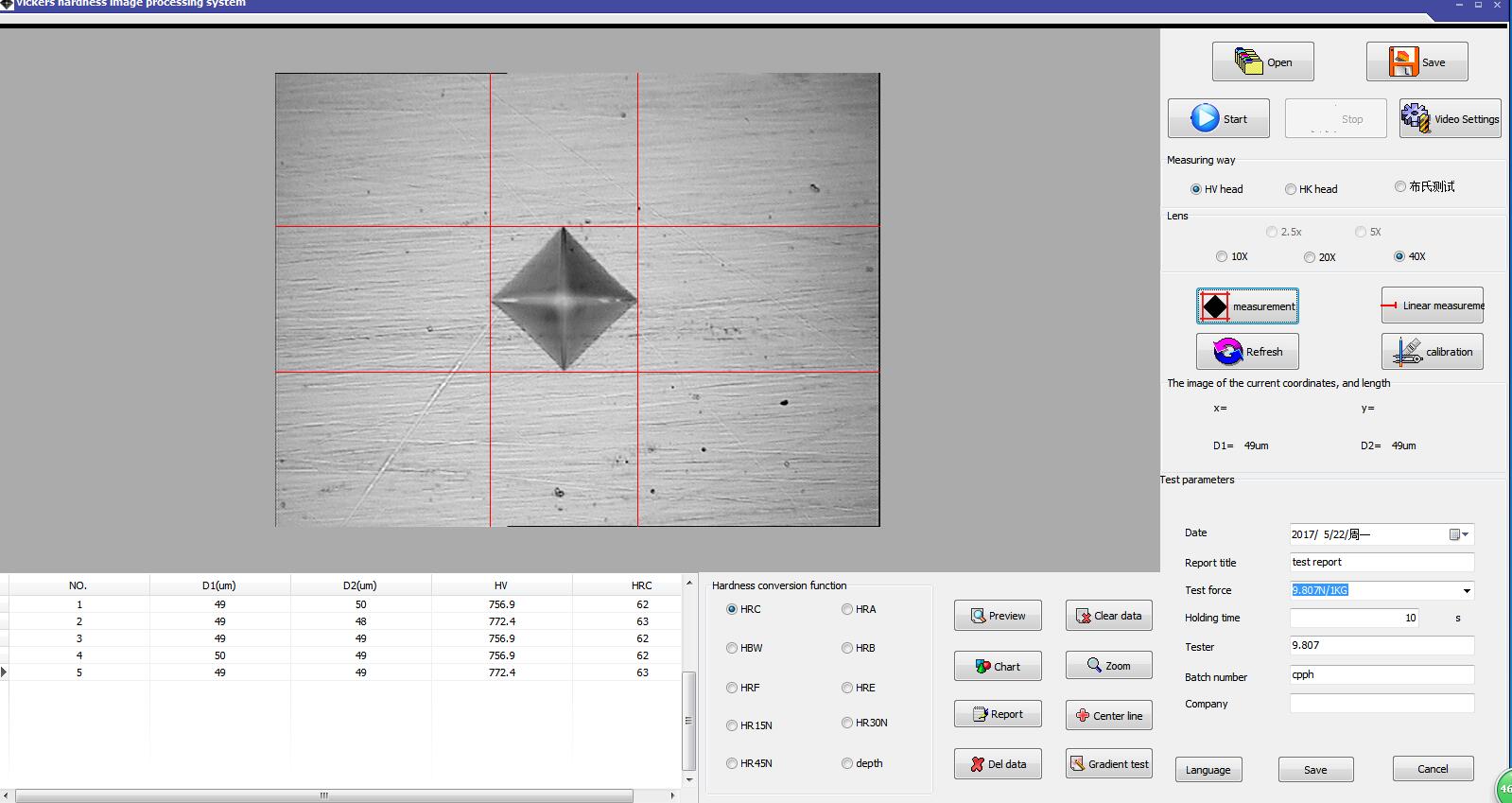

Optional CCD Data Processing Software:

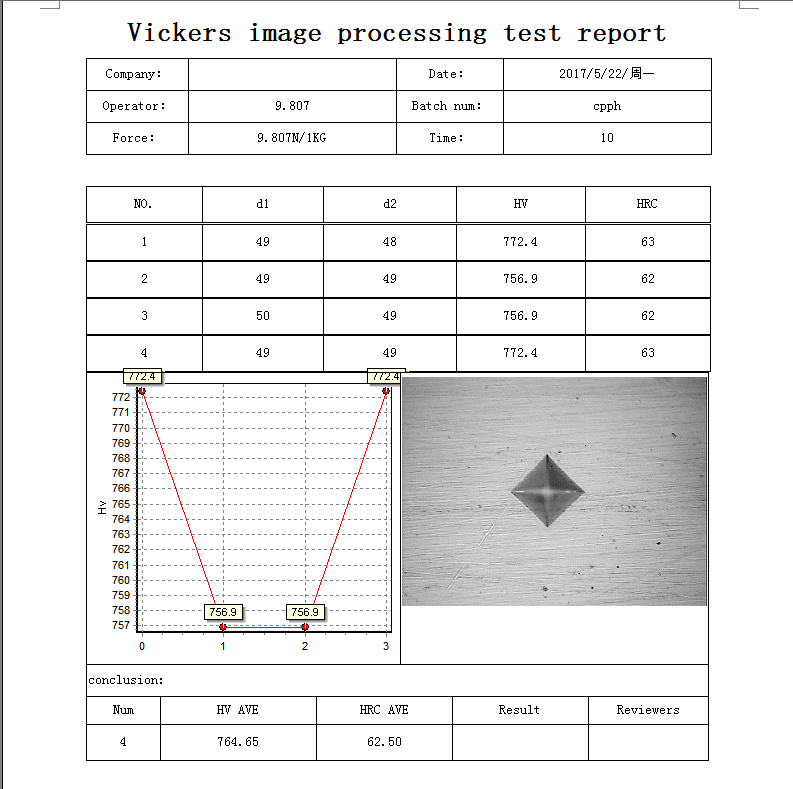

CCD Software Interface

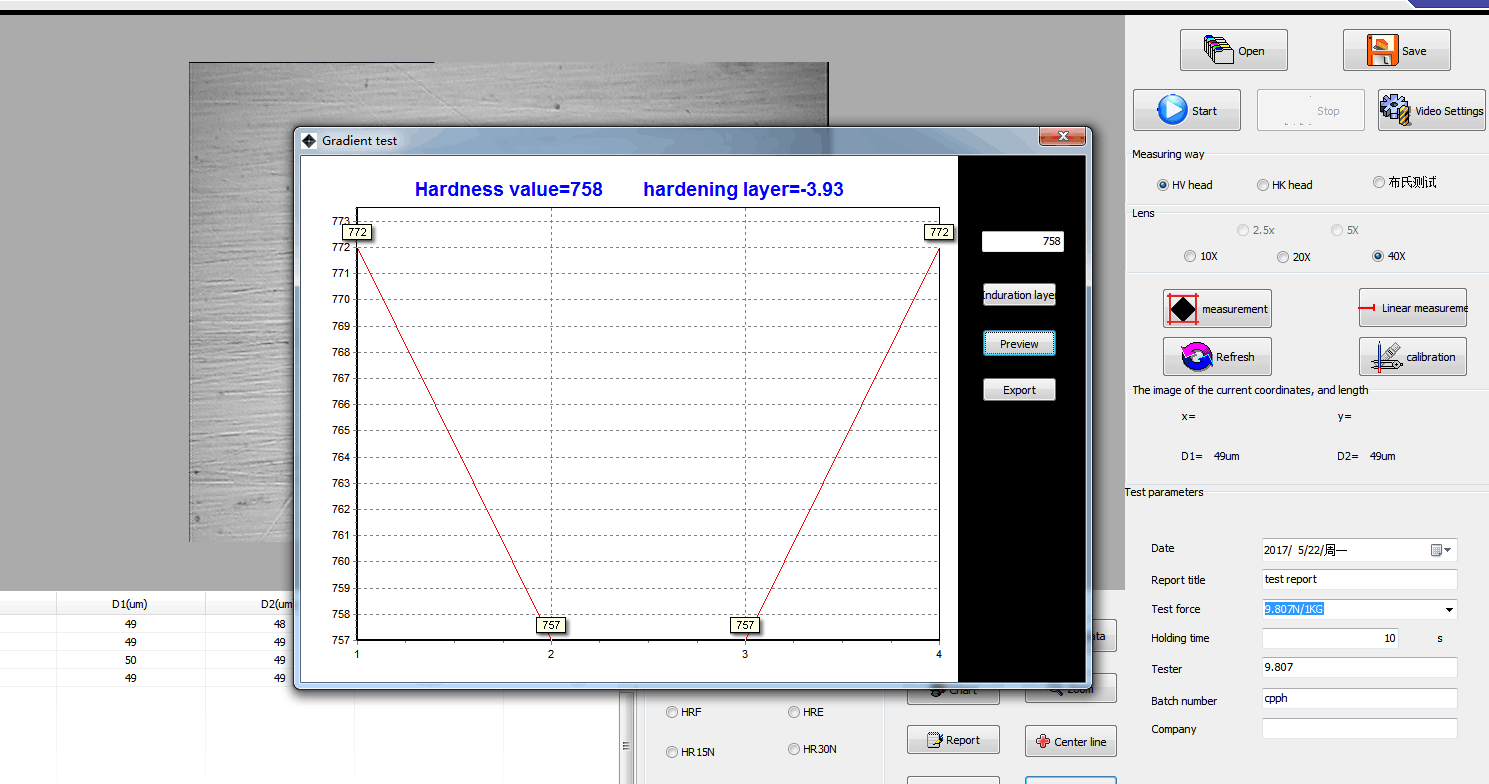

Gradient Test

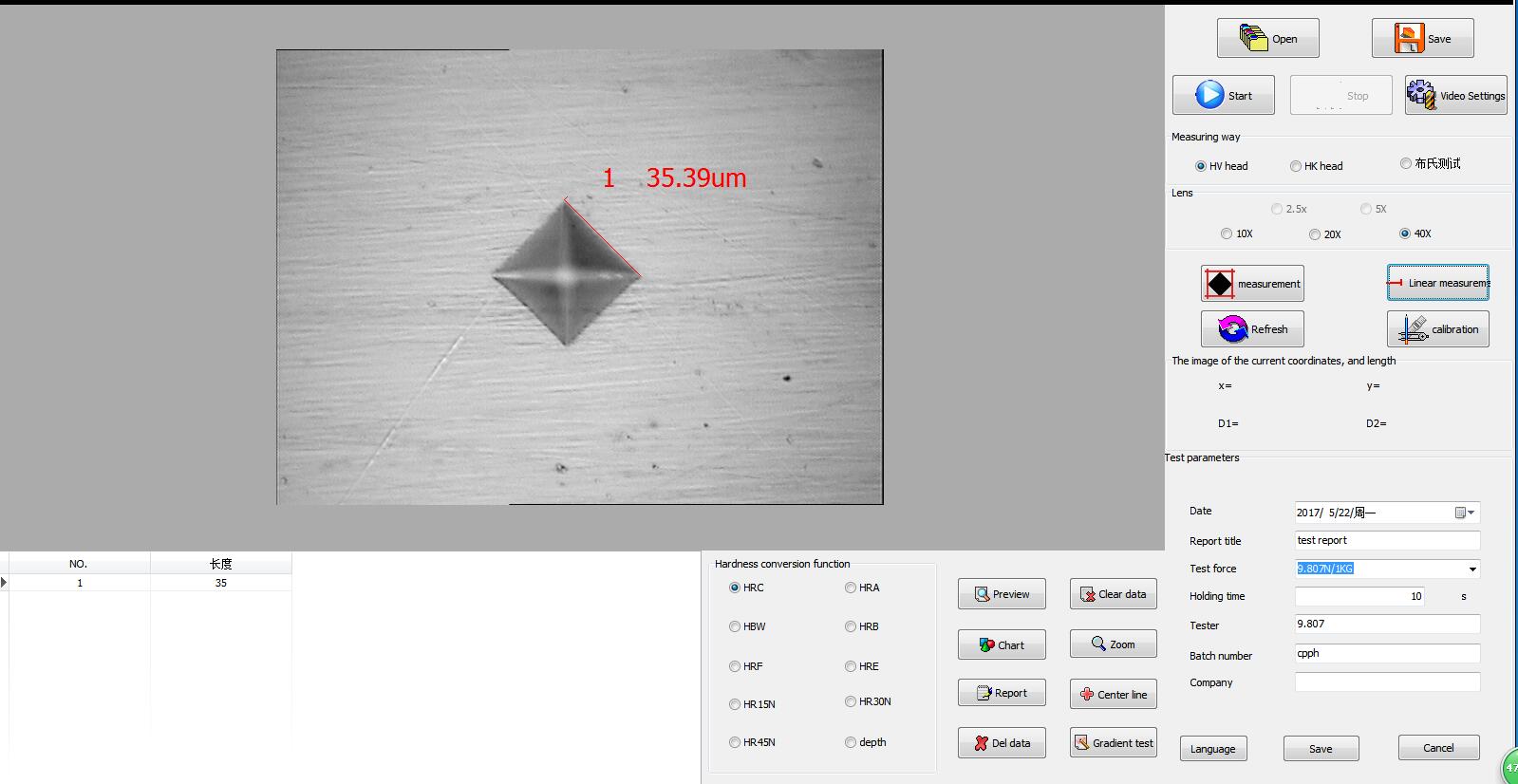

Indentation Length Test

Test Report