Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

Product : Portable Hardness Tester

Model : DH250

Country of Origin : CHINA

Brand : DTEC

Quality Certified : CE,GB/T 17394-1998, ASTM A956

Delivery Time : 3 days

Packing Weight : 6KG

Dimension : 37x30x12cm(LxWxH)

Package Type : Maker's Standard Export Carton

Courier : DHL/TNT/FedEx/UPS/EMS/Shipping Agent

Payment Term : TT100%/Private Bank Account/L/C/Paypal/Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

operation temperature and high accuracy etc.

It is applicable to big workpiece on-site hardness testing and batch testing on the workpiece in production lines.

Moreover, it is also used in metal manufacturing industry, transportation, power station, petrochemical industry, aircraft industry, construction and lab, etc.

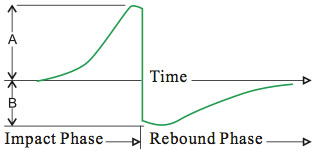

Working Principle:

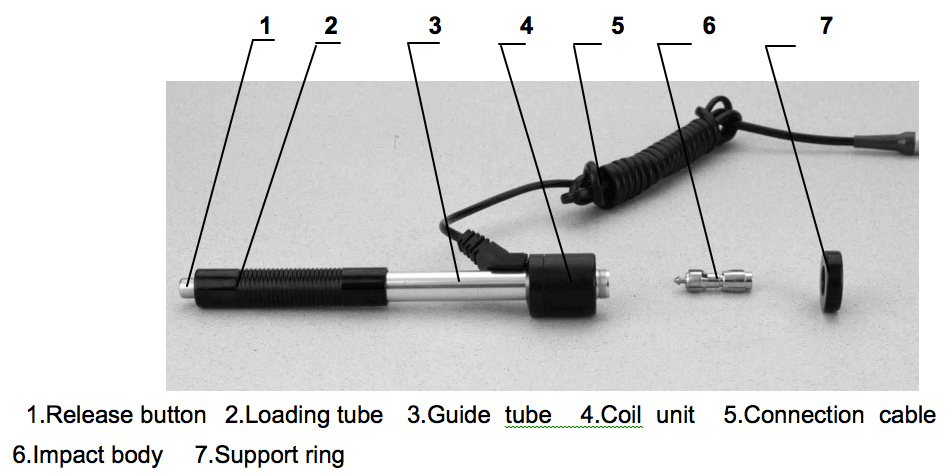

When the impact body,with a certain weight,impacts against the specimen surface under the action of spring force,leeb hardness comes from the ratio of the impacting velocity(VA) and the rebounding velocity(VB) of the impact body by the moment the spherical testing tip is located at 1mm point from specimen surface.

With principle of electromagnetism,the permanent magnet in the coil of impact device produced an induced voltage, which is in proportion to the impact body velocity.

The leeb hardness values are calculated by the following formula:

HL=1000X(Vb/Va)

Using Scopes:

Die cavity of molds.

Bearings and other parts.

Failure analysis of pressure vessel, steam generator and other equipment.

Heavy work piece.

The installed machinery and permanently assembled parts.

Testing surface of a small hollow space.

Material identification in the warehouse of metallic materials.

Rapid testing in large range and multi-measuring areas for large-scale work piece.

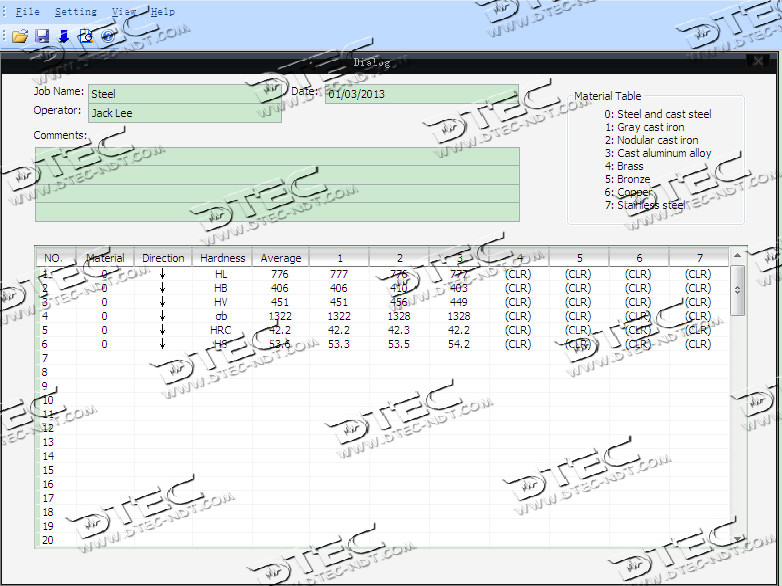

►6 exchangeable hardness scales (HRB/HRC/HV/HB/HS/HL),measurable for the hardness strength σb;

►8 kinds of material available, suitable to measure the hardness of all metallic materials;

►600 groups storage capacity, including 0-7 measured value, average value, testing data, impact direction, impact times, material and hardness scale etc.;

►High contrast segment liquid crystal display, displaying figures, with EL background light;

►With standard data processing software and USB cable, enable to connect to PC and make further data analysis;

►High accuracy in any impact direction (360°), automatically identify impact direction as well as impact device type and gravity compensation;

►Excellent after-sale service system for high quality products,easy to buy and convenient to use.

|

Testing Range

|

HLD(200-960),HRC(19.8-68.5), HRB(13.5-100), HB(30-651), HV(80-976), HS(26.4-99.5), σb (375-2639). |

|

Hardness Scale

|

HL, HB, HRB, HRC, HV, HS, σb.

|

|

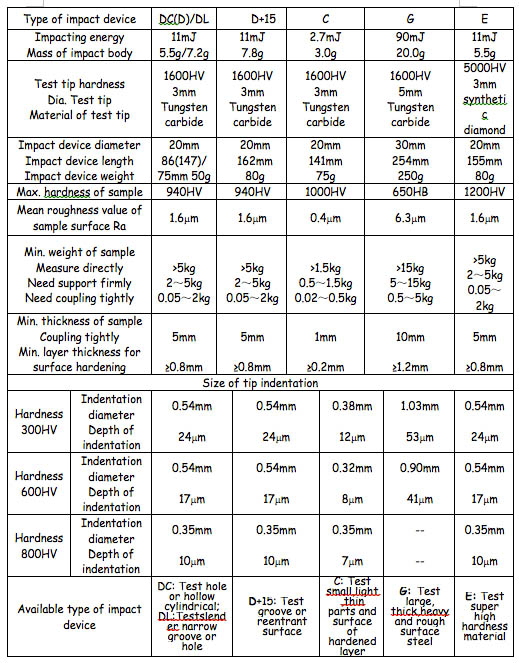

Impact Device

|

Standard Type: D, Optional Type: C/G/DC/DL/D+15

|

|

Accuracy

|

±6HLD (HLD=800), Repeatability: <6HLD (HLD=800)

|

|

Resolution

|

1HL, 1HV, 1HB, 0.1HRB, 0.1HRC, 0.1HS |

|

Testing Direction

|

360 Degree by Manual Setting

|

|

Display

|

High Contrast Segment Liquid Crystal Display (Display Only Figure), LED Backlight. |

|

Available Material

|

Steel& Cast Steel, Stainless Steel, GC iron, NC iron, Cast Aluminum alloy, Copper-zinc alloy, Copper-tin alloy, Brass. |

|

Storage

|

600 Groups (each group include 1-7 testing results and 1 average value) |

|

Communication

|

Standard: USB port , Optional: Bluetooth |

|

Working Temp.

|

-10°C—+50°C

|

|

Power Supply

|

2 AA Batteries

|

|

Dimension

|

37x30x12cm (LxWxH)

|

|

Packing Weight

|

About 6.0 KG

|

|

Quality Standard

|

GB/T 17394-1998, ASTM A956

|

Error and Repeatability of Displayed Value:

|

No.

|

Type of impact device

|

Hardness value of Leeb standard hardness block |

Error of displayed value |

Repeatability

|

|

1

|

D

|

760±30HLD

530±40HLD

|

±6 HLD

±10 HLD

|

6 HLD

10 HLD

|

|

2

|

DC

|

760±30HLDC

530±40HLDC

|

±6 HLDC

±10 HLDC

|

6 HLD

10 HLD

|

|

3

|

DL

|

878±30HLDL

736±40HLDL

|

±12 HLDL

|

12 HLDL

|

|

4

|

D+15

|

766±30HLD+15

544±40HLD+15

|

±12 HLD+15

|

12 HLD+15

|

|

5

|

G

|

590±40HLG

500±40HLG

|

±12 HLG |

12 HLG |

|

6

|

E

|

725±30HLE

508±40HLE

|

±12 HLE |

12 HLE |

|

7

|

C

|

822±30HLC

590±40HLC

|

±12 HLC

|

12 HLC

|

Testing Range in Different Materials with Different Impact Devices:

|

Material

|

Method

|

Impact device

|

|||||

|

D/DC

|

D+15

|

C

|

G

|

E

|

DL

|

||

|

Steel and cast steel

|

HRC

|

20~68.5

|

19.3~67.9

|

20.0~69.5

|

|

22.4~70.7

|

20.6~68.2

|

|

HRB

|

38.4~99.6

|

|

|

47.7~99.9

|

|

37.0~99.9

|

|

|

HRA

|

59.1~85.8

|

|

|

|

61.7~88.0

|

|

|

|

HB

|

127~651

|

80~638

|

80~683

|

90~646

|

83~663

|

81~646

|

|

|

HV

|

83~976

|

80~937

|

80~996

|

|

84~1042

|

80~950

|

|

|

HS

|

32.2~99.5

|

33.3~99.3

|

31.8~102.1

|

|

35.8~102.6

|

30.6~96.8

|

|

|

Cold work

tool steel

|

HRC

|

20.4~67.1

|

19.8~68.2

|

20.7~68.2

|

|

22.6~70.2

|

|

|

HV

|

80~898

|

80~935

|

100~941

|

|

82~1009

|

|

|

|

Stainless steel

|

HRB

|

46.5~101.7

|

|

|

|

|

|

|

HB

|

85~655

|

|

|

|

|

|

|

|

HV

|

85~802

|

|

|

|

|

|

|

|

Grey cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

93~334

|

|

|

92~326

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Nodular cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

131~387

|

|

|

127~364

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Cast aluminum alloys

|

HB

|

19~164

|

|

23~210

|

32~168

|

|

|

|

HRB

|

23.8~84.6

|

|

22.7~85.0

|

23.8~85.5

|

|

|

|

|

BRASS(copper-zinc alloys)

|

HB

|

40~173

|

|

|

|

|

|

|

HRB

|

13.5~95.3

|

|

|

|

|

|

|

|

BRONZE(copper-aluminum/tin alloys)

|

HB

|

60~290

|

|

|

|

|

|

|

Wrought copper alloys

|

HB

|

45~315

|

|

|

|

|

|

|

No.

|

Items

|

Qty.

|

|

1

|

DH250 Main Unit

|

1

|

|

2

|

D Type Impact Device

|

1

|

|

3

|

Standard Hardness Block

|

1

|

|

4

|

Cleaning Brush

|

1

|

|

5

|

Small Support Ring

|

1

|

|

6

|

2 AA Battery

|

1

|

|

7

|

Protective Rubber Sheath

|

1

|

|

8

|

Manual, Warranty Card, Quality Certificate |

1 each

|

|

9

|

Data Pro Software and USB Cable

|

1

|

|

10

|

Package Case

|

1

|

|

No.

|

Items

|

Notes

|

|

1

|

Impact Device

|

(D/C/G/DC/DL/D+15)

|

|

2

|

Impact Body

|

For all Types: D/C/G/DC/DL/D+15

|

|

3

|

Cable for Impact Device

|

1.5M long,3-pin cable

|

|

4

|

Supporting Ring

|

Standard Type and Special Type, 12pcs/set |

|

5

|

Data Processing Software & USB Cable |

|

|

6

|

Standard Leeb Hardness Testing Block |

750-850HLD,590-670HLD,490-570HLD,550-630HLG,460-540HLG

|

|

7

|

Blue Tooth Wireless Thermal Mini Printer |

|

|

8

|

Belt

|

1.2 M Long

|

|

9

|

Instrument Case

|

35x28x10cm(LxWxH)

|

Impact Devices(D/C/DC/DL/D+15/G)

3-Pin Cable for Impact Device (D/C/DC/DL/D+15/G), 1.5M in length

Impact Body (D/C/DC/DL/D+15/G)

Supporting Rings(12 pcs. each set)

Specification of Supporting Rings:

Data Processing Software (including USB cable)

Standard Leeb Hardness Testing Block

|

Items

|

Size

|

Dimension

|

Product Picture

|

|

|

750-850HLD

|

Ф 90 × 55 mm |

|

|

590-670HLD

|

|||

|

490-570HLD

|

|||

|

550-630HLG

|

Ф120 × 70 mm |

||

|

460-540HLG

|

|||

|

AA Grade Leeb Hardness Standard Block |

750-850HLD

|

Ф 90 × 55 mm |

|

|

590-670HLD

|

|||

|

490-570HLD

|

|||

|

550-630HLG

|

Ф120 × 70 mm |

||

|

460-540HLG

|