Contact Us

Tel: +86-10-89207378

Fax: +86-10-89207378

Mobile: +86-13811339497 same ID for WeChat and WhatsApp

E-mail: info@dtec-ndt.com

Skype: stillsuccess1

|

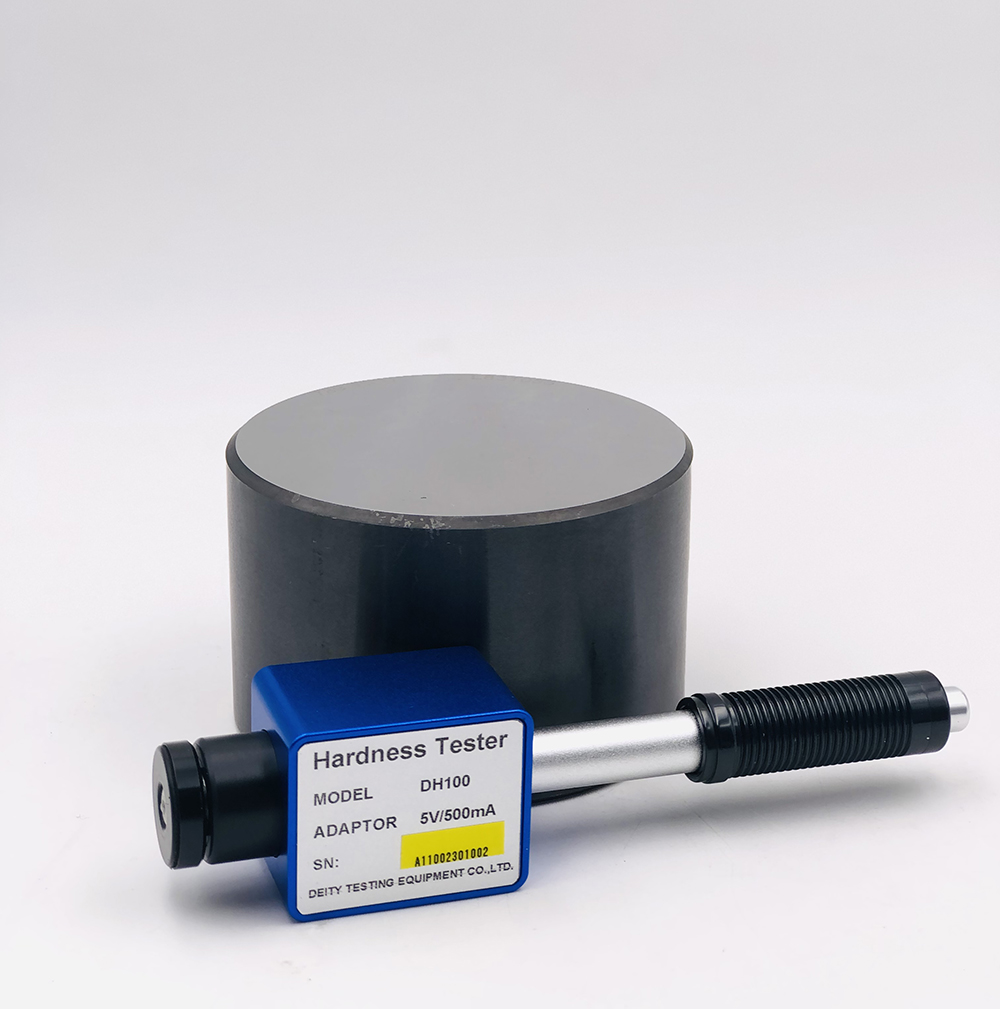

Product : Pen Style Leeb Hardness Tester(D)

Model : DH100D

Country of Origin : China

Brand : DTEC

Quality Certified : CE,ISO

Delivery Time : 3 days

Packing Weight : 5.5KG

Dimension : 33x28x15cm(LxWxH)

Package Type : Carton

Courier : DHL,TNT,FedEx,UPS,EMS,Shipping Agent

Payment Term : TT,Private Bank Account,LC,Paypal,Western Union

|

- Product Intro

- Feature

- Specification

- Packing List

DH100 pocket-size leeb hardness tester can directly measure different types of hardness value including (HRC, HRB, HRA), Leeb (HL), Brinell (HB), Vickers (HV),and Shaw (HS). In accord with international standards it's also can meet the "Leeb hardness tester technical conditions ZBN7l 010-90" and the "metal in the hardness test method GB / T 17394-1998" Leeb hardness standard JB/ T9378-2001 standards which are issued by the Ministry of Machinery Industry and National Quality and Technical Supervision.

With low-power design and high-performance Li batteries which can achieve ultra-long standby time work it has more compact and flexible design increases user flexibility.

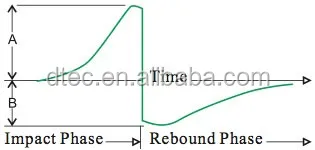

Working Principle:

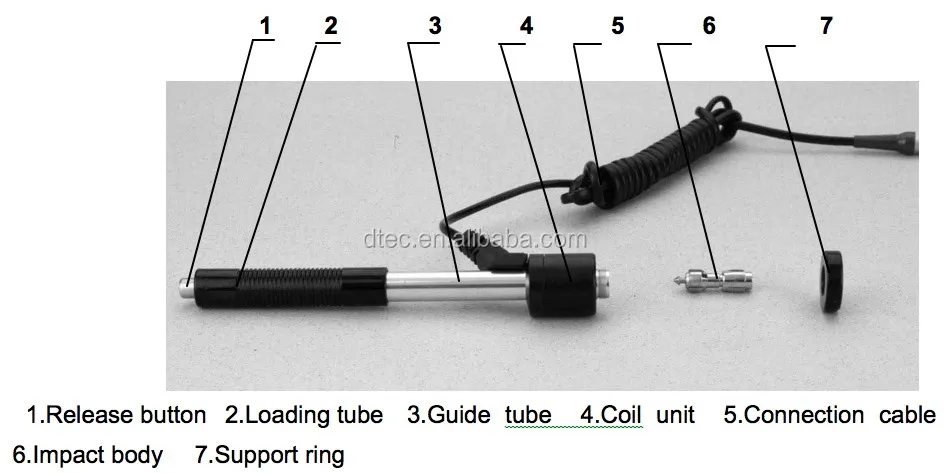

When the impact body,with a certain weight,impacts against the specimen surface under the action of spring force,leeb hardness comes from the ratio of the impacting velocity(VA) and the rebounding velocity(VB) of the impact body by the moment the spherical testing tip is located at 1mm point from specimen surface.

With principle of electromagnetism,the permanent magnet in the coil of impact device produced an induced voltage, which is in proportion to the impact body velocity.

The leeb hardness values are calculated by the following formula:

HL=1000X(Vb/Va)

Main Application:

- Die cavity of molds

- Bearings and other parts

- Failure analysis of pressure vessel, steam generator and other equipment

- Heavy work piece

- The installed machinery and permanently assembled parts

- Testing surface of a small hollow space

- Material identification in the warehouse of metallic materials

- Rapid testing in large range and multi-measuring areas for large-scale work piece

- Full English menu display,easy to manipulate. OLED display for better use in any environments;

- With Micro USB communication port;

- Suitable for three types of impact devices:D/DL/G,can meet various condition of testing workpieces;

- Bluetooth module included, it can communicate with Bluetooth printer, mobile phone and PC;

- Large memory capacity,can store 373~2688 groups (impact average times32~1) of information including single measured value, mean value, testing date, impact direction, impact times, material and hardness scale etc. ;

- Conversion to tensile strength (U.T.S);

- Suitable for all metallic materials;

- Provide software calibration function;

- High-performance Li battery with charging circuit providing extra-long working time and standby time. Battery sign displays the current remaining power;

- PC Software can be equipped to meet the higher demands in quality assurance, activities and management.

|

Model

|

DH100

|

|

Hardness scale

|

HL, HRC, HRB, HRA, HV, HB, HS

|

|

Measuring range

|

HLD(170 ~ 960), HRA(59 ~ 85), HRB(13 ~ 100), HRC(20 ~ 68),

HB(19 ~ 651), HV(80 ~ 967), HS(30 ~ 100)

|

|

Clock

|

Real-time data and time

|

|

Auto off

|

3~5 Minutes without any operation

|

|

Data Interface

|

USB,Blue tooth

|

|

Power

|

Rechargeable Li Battery, 3.7V

|

|

Memory

|

373~2688 group (Impact times: 32~1)

|

|

Display

|

128 × 36 OLED

|

|

Continuous Working time

|

About 30h

|

|

Charging time

|

1.5 ~ 2 hours

|

|

Overall dimensions

|

148 × 33 × 30 mm

|

|

Weight

|

95g

|

Error and Repeatability of Displayed Value:

|

No.

|

Type of impact device

|

Hardness value of Leeb standard hardness block

|

Error of displayed value

|

Repeatability

|

|

1

|

D

|

760±30HLD

530±40HLD

|

±6 HLD

±10 HLD

|

6 HLD

10 HLD

|

|

2

|

DC

|

760±30HLDC

530±40HLDC

|

±6 HLDC

±10 HLDC

|

6 HLD

10 HLD

|

|

3

|

DL

|

878±30HLDL

736±40HLDL

|

±12 HLDL

|

12 HLDL

|

|

4

|

D+15

|

766±30HLD+15

544±40HLD+15

|

±12 HLD+15

|

12 HLD+15

|

|

5

|

G

|

590±40HLG

500±40HLG

|

±12 HLG

|

12 HLG

|

|

6

|

E

|

725±30HLE

508±40HLE

|

±12 HLE

|

12 HLE

|

|

7

|

C

|

822±30HLC

590±40HLC

|

±12 HLC

|

12 HLC

|

Testing Range in Different Materials with Different Impact Devices:

|

Material

|

Method

|

Impact device

|

|||||

|

D/DC

|

D+15

|

C

|

G

|

E

|

DL

|

||

|

Steel and cast steel

|

HRC

|

20~68.5

|

19.3~67.9

|

20.0~69.5

|

|

22.4~70.7

|

20.6~68.2

|

|

HRB

|

38.4~99.6

|

|

|

47.7~99.9

|

|

37.0~99.9

|

|

|

HRA

|

59.1~85.8

|

|

|

|

61.7~88.0

|

|

|

|

HB

|

127~651

|

80~638

|

80~683

|

90~646

|

83~663

|

81~646

|

|

|

HV

|

83~976

|

80~937

|

80~996

|

|

84~1042

|

80~950

|

|

|

HS

|

32.2~99.5

|

33.3~99.3

|

31.8~102.1

|

|

35.8~102.6

|

30.6~96.8

|

|

|

Cold work

tool steel

|

HRC

|

20.4~67.1

|

19.8~68.2

|

20.7~68.2

|

|

22.6~70.2

|

|

|

HV

|

80~898

|

80~935

|

100~941

|

|

82~1009

|

|

|

|

Stainless steel

|

HRB

|

46.5~101.7

|

|

|

|

|

|

|

HB

|

85~655

|

|

|

|

|

|

|

|

HV

|

85~802

|

|

|

|

|

|

|

|

Grey cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

93~334

|

|

|

92~326

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Nodular cast iron

|

HRC

|

|

|

|

|

|

|

|

HB

|

131~387

|

|

|

127~364

|

|

|

|

|

HV

|

|

|

|

|

|

|

|

|

Cast aluminum alloys

|

HB

|

19~164

|

|

23~210

|

32~168

|

|

|

|

HRB

|

23.8~84.6

|

|

22.7~85.0

|

23.8~85.5

|

|

|

|

|

BRASS(copper-zinc alloys)

|

HB

|

40~173

|

|

|

|

|

|

|

HRB

|

13.5~95.3

|

|

|

|

|

|

|

|

BRONZE(copper-aluminum/tin alloys)

|

HB

|

60~290

|

|

|

|

|

|

|

Wrought copper alloys

|

HB

|

45~315

|

|

|

|

|

|

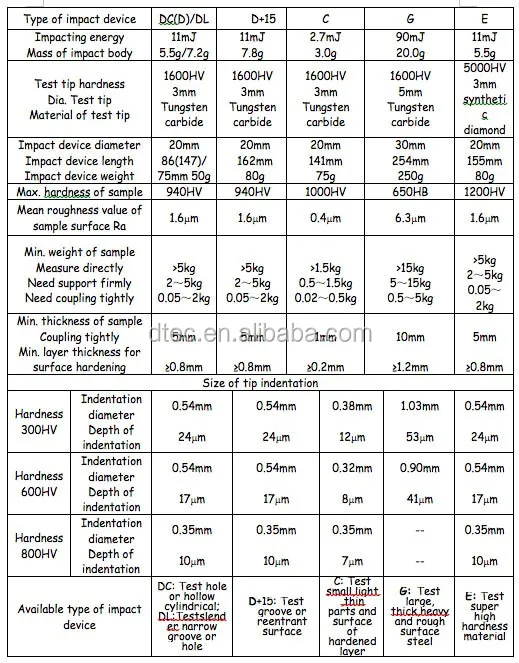

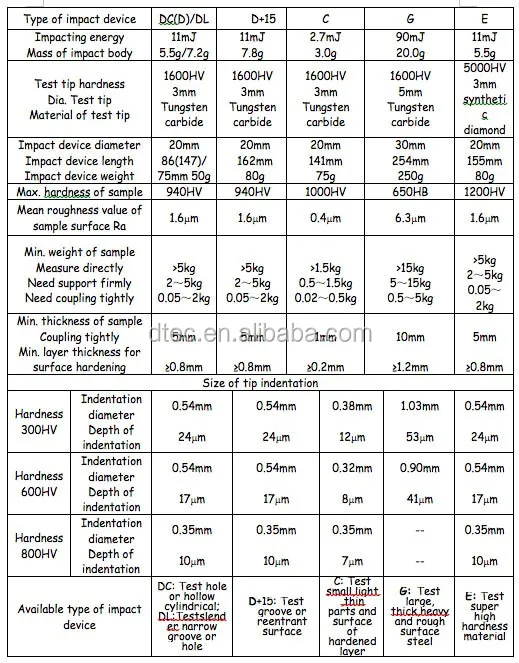

Testing Parameter of Impact Devices:

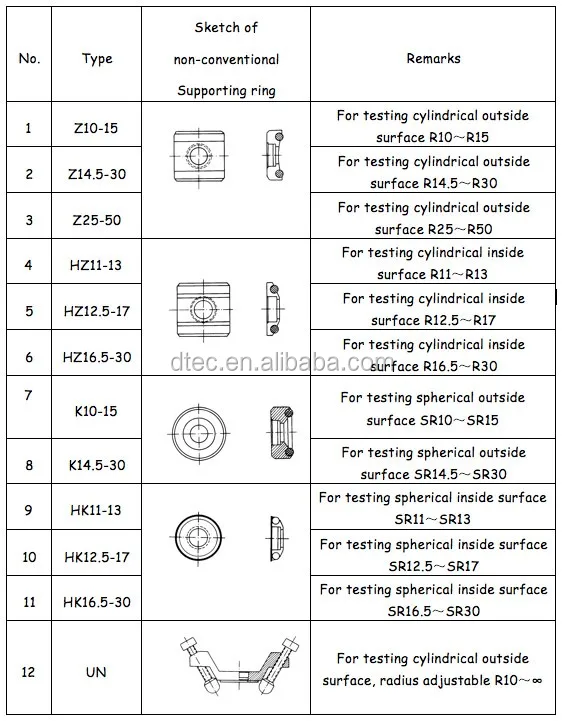

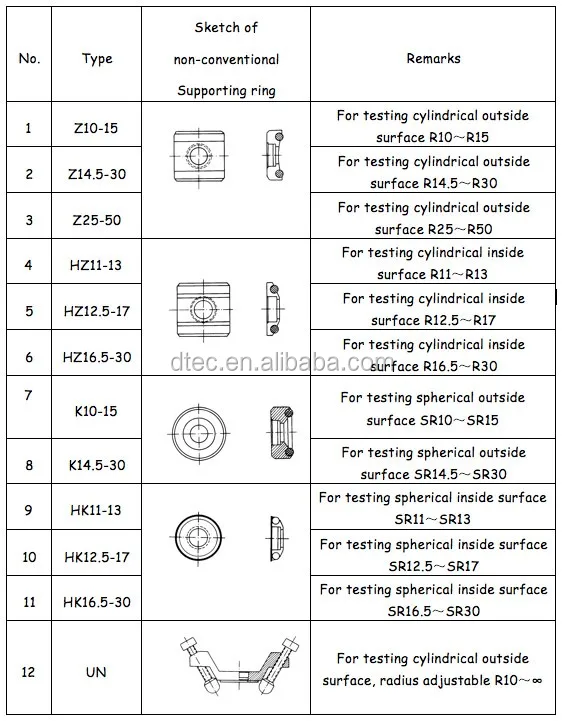

Specification of Supporting Rings:

|

No.

|

Items

|

Qty.

|

|

1

|

DH100 Main Unit (D)

|

1

|

|

2

|

D type Standard Hardness Block

|

1

|

|

3

|

Cleaning Brush

|

1

|

|

4

|

Small Support Ring

|

1

|

|

5

|

chargeable Polymer lithium battery(installed inside unit)

|

1

|

|

6

|

Charger

|

1

|

|

7

|

Manual, Warranty Card, Quality Certificate

|

1 each

|

|

8

|

Data Pro Software Disk and USB Cable

|

1

|

|

9

|

Package Case

|

1

|

Optional Accessories:

|

No.

|

Items

|

Notes

|

|

1

|

Impact Device

|

DL/G Type

|

|

2

|

Impact Body

|

For DL/G Type

|

|

3

|

Supporting Ring

|

Standard Type and Special Type, 12pcs/set

|

|

4

|

Data Processing Software & USB Cable

|

|

|

5

|

Standard Leeb Hardness Testing Block

|

750-850HLD,590-670HLD,490-570HLD,550-630HLG,460-540HLG

|

|

6

|

Blue Tooth Wireless Thermal Mini Printer

|

|

|

7

|

Instrument Case

|

28x20x15cm(LxWxH)

|

Standard Leeb Hardness Testing Block:

Impact Devices(This model only suitable for D and DL Type)

Cables for Impact Device(1.5M in Length):

Supporting Rings(12 pcs. each set):